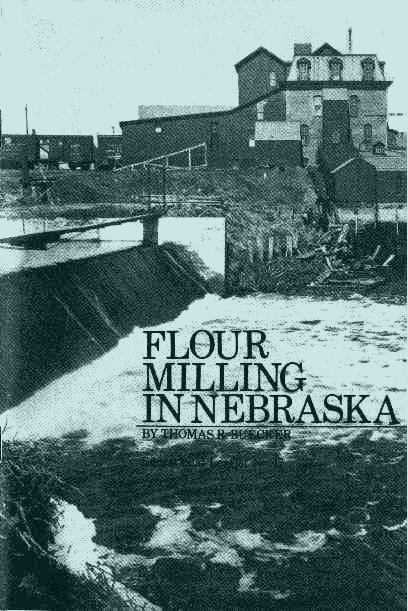

Cover: Neligh Mills, now a Society Branch Museum, about 1906.

Published by the Nebraska State Historical

Society, 1500 R,

Lincoln 68508

The small flour mill is a part of our heritage that has almost totally disappeared from the Nebraska countryside. In the nineteenth century and well into the twentieth there were mills in almost every county of the state, with even the smallest of towns having a mill. The growth of the milling industry paralleled that of the state, with mills following close behind the settlers. Grist mills filled a necessary role, that of processing area grain into foodstuffs and, as a local industry, providing jobs. Besides those services, a flour mill boosted a community's economy by attracting farmers who sold their grain and patronized the town merchants. Although the march of progress passed by the small mills, it is interesting today to examine the development of milling in Nebraska and the different aspects of this pioneer industry.

The earliest grist mill in Nebraska was established at Fort Atkinson in the 1820s. At that time this military post was the farthest western settlement in the United States. The soldiers there spent a large part of their time farming and producing foodstuffs for themselves because they were so far from the food producing centers of the eastern states. To grind their corn and wheat, a millwright was brought to the post and a grist mill constructed in the fall of 1821. The mill, powered by draft animals, was able to grind 150 bushels of grain a day. Using the same power source, a sawmill cutting 1500 feet of planks per day was also put into operation. In the year 1824, the mill was able to produce 200 barrels of flour valued at $6.25 1/2 per barrel. On July 5, 1825, the mill was destroyed by a storm, two years before Fort Atkinson was abandoned.

After the Kansas-Nebraska Act of 1854, Nebraska Territory was open to settlement, with the eastern part of the state being the first area settled. It was discovered early in this period that the soil and climate of southeast Nebraska were very favorable to raising cereal grains. Wheat could be easily and abundantly grown. The new settlers needed flour, and, with the slow and inadequate transportation of the period, the demand appeared for mills to grind flour locally. Realizing this, enterprising settlers with some knowledge of the milling process imported stone burrs, or millstones, to grind the wheat and reels to sift the finer particles and thus established flour mills.

By 1860 at least 19 grist mills had been built in the territory. Many of these early mills, such as at DeSoto and Plattsmouth, were operated in conjunction with sawmill activities and used steam as a power source. Because the early settlements were along the Missouri River, steamboats could bring in heavy boilers and

A typical stone burr mill of the 1860s was a two-story stone or wood building about 30 by 40 feet in size. On the first floor one or two stone burrs ground the wheat. Usually another stone was installed to grind cornmeal or livestock feeds. Also on the first floor was a sacking area where flour was put into sacks or wooden barrels. Elevator legs took the grain, by means of continuous belting with small cups fastened on, to the second floor where the storage bins were located. Here too were located reels to sift the finer flour from the ground wheat. Usually the mill was situated close to a stream or river to take advantage of the available water power, preferably high enough above normal water level to avoid flood damage. A dam was constructed to build up a sufficient head of water, on the average 8 to 12 feet. The mill was powered by means of a flume and a water turbine. In some instances a general store or postoffice opened near the mill forming a nucleus for a small community. In Hall County the small community of Runnelsburgh contained a grist mill, general store, and postoffice, and was named for the settler who operated all three. Small mill communities such as this were once common in the early years of the state.

As settlement moved across the state, farmers in many cases had to travel great distances to have their wheat ground into flour. Harrison Johnson's early history of Nebraska states that in the early 1860s when Fort Calhoun had the only flour mill north and west of Omaha, settlers often came 100 miles to the mill. As a result of the need and the great distances involved between existing mills, mills gradually began to increase in number.

At the mill the farmers either exchanged their wheat for flour or sold it outright to the miller, whose market was almost exclusively within his own community. When exchanging wheat for flour, the miller usually received one-eighth of the wheat brought in to be ground as his toll or exchange charge. The farmer also had the option of selling his grain outright to the mill. In the 1870s and 1880s wheat usually brought 50 to 60 cents a bushel, and a good crop could average about 20 bushels to the acre. The miller then ground the wheat into flour, which he sold for $5.00 to $8.00 a barrel (a barrel is 196 lbs.), the price depending on the time of year with higher prices in the winter months. Because of a lack of transportation and grain storage facilities, the early millers had to

In the post Civil War years the Homestead Act and the expansion of the railroads brought thousands of settlers and caused a further increase in the need for mills. By 1870 flour milling was the leading industry of the state, with 183 employees working at 60 mill locations. The following table compares the growing population of the state with the increase in number of mills in operation:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Because a mill was so valuable to a new town's growth, on many occasions the citizens offered bonds, bonuses, or other donations to secure a mill. To encourage the location of a mill in Fairmont, the citizens donated a $1,000 bonus to the first mill proprietor. In Oakdale the parties who purchased the original town site were required by the seller to put up a $10,000 bond for the erection of a flour mill. However, bond subscription was declared by the courts to be illegal in several instances, and towns had to resort to other means to attract a flour mill. In 1891 the citizens of Beemer paid Henry Lambrecht $1,200 to move his mill into town. Miller Lambrecht had one of the finest residences in

The decade of the 1880s brought a radical change to flour milling, the introduction of steel rollers. Stone burr mills, which had been used for centuries to grind flour, were not able to completely reduce the wheat kernels into flour. The stone ground flour was more susceptible to spoilage because the bran and germ could not be completely removed. The small amount of oil in the germ would become rancid or would spoil after a period of time. The new roller process of milling solved this problem.

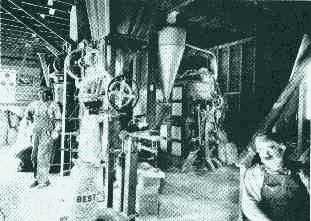

One or two of the roller stands, called break rollers, contained rolls with very coarse corrugates. These would "break" the wheat kernels when they passed through. The broken wheat would then be elevated to the floor above where the machines called purifiers removed the bran and germ with a blast of air. The larger pieces of wheat were sent through finer, or reduction, rollers to be further ground down. The ground wheat was then elevated to the upper floors of the mill where the flour was sifted away; the particles not fine enough for flour were returned through the reduction rollers to be ground again. Wheat was reduced to flour by a gradual reduction process. The bran and germ, together known as offal, were removed for other purposes. To house the extra machinery required by the more efficient roller process, mill buildings had to have at least three floors and a basement.

Millers were now able to grind down the middlings and thereby manufacture more flour from the wheat they bought from the farmers. Besides producing more and purer flour, the rollers were many times faster than the stone burrs. A mill's daily capacity could be increased as much as ten times.

Across Nebraska progressive millers by the score removed their stone burrs and replaced them with steel rollers. Sometimes the change required a new mill building or, at the least, extensive remodeling. Although the installation of the new machinery was very expensive, millers quickly realized that increased production and a better product would bring increased sales. The era of the stone burr mill was over. With the stone burrs being removed, the term "grist mill" also disappeared. Flour mills then became known as "roller mills" named after the steel rollers so important in the "modern" process. The rapid conversion of Nebraska mills to the new process was facilitated greatly by the continued expansion of railroad transportation in the 1880s and 1900s.

Because water power was cheap and readily available in many areas, it was the power source used almost exclusively by the early mills. In fact, location of the mill on a good stream was a vital factor for its success. A water-powered mill brought other benefits to townspeople. The mill ponds created by damming a

5

However, the use of water power had its disadvantages, particularly when a dam broke or washed out and milling operations had to be suspended while repairs were made. During dry summer months many streams did not have enough water to power the turbine. Freezing winter weather and high water also hampered operations. Periods of inactivity affected local business because farmers would not come into town to trade with no mill to visit. While the local mill dam was being repaired at Neligh in 1883, the newspaper encouragingly remarked:

Work during the past week has been progressing rapidly upon the damWater power was plentiful in the eastern part of the state, but it was not totally reliable to power the mills. During the 1900s many water-powered mills, for one reason or another, converted to steam or the new power sources that came with the twentieth century-diesel and electrical power. The number of waterpowered mills began to decline.

As stated earlier, in the 1850s there were several steampowered mills operating along the Missouri River. Steamboats could freight in the heavy machinery necessary for generating steam power, but the steam plants were difficult to transport inland. Moving steam engines and boilers overland in the early days proved to be a very difficult task as there were no roads and the streams were not bridged. With the upsurge of railroad construction, steam-power equipment could easily be freighted to points beyond the river, and a change to Nebraska milling began. Not having to depend on water power, flour mills now appeared in settlements where there was no nearby stream or river. Lexington, Friend, and Brainard are examples of towns with no nearby water power where steam-powered mills were built along the railroad. As a result, the availability of steam-power became a valuable asset to many towns.

Along with water and steam, another power source occasionally harnessed in the nineteenth century was the wind. Wind power was utilized by some millers to power grist mills, and quite successfully in some cases. The advantage of a wind-powered mill was that it could be built in the heart of wheat growing areas, far from a stream. In the 1870s a windmill generating ten horsepower was used to run two stone burrs grinding 50 bushels of wheat a day by one Carl Boehl of Hall County. One of the first attempts at milling in Wisner was with a "fearfully and wonderfully made" windmill which ground wheat into reasonably good flour. This windmill operated for four years, but high winds blew the wheel down twice, the last time completely destroying the mill. In disgust the owner pulled up and moved to a water-powered site near Wood Lake. Bennet had a wind-powered mill built in 1875 by A. G. Strang of Omaha. A 60-foot Halladay windmill wheel, which generated 40 horsepower in a 12-mile wind, provided power to run three stone burrs. Despite successful operation for several years, it was converted into a steam-powered roller mill in the 1880s. Ironically, the source of power for these mills, the wind, could easily destroy them. Consequently this type of mill was rarely seen in the state.

After experience proved that Nebraska's soil and climate produced good grain crops, there were several decades of mill building activity. This was true across all the midwestern states. As the population of the plains states increased, so did the need for mills. The number of mills in Nebraska grew from 177 in 1880 to over 270 by 1900. Production increased at the same rate as well.

Besides creating a grain market for local farmers, grinding flour and other cereal grains, and producing livestock feeds, the flour mills brought the first electricity to some Nebraska communities. With local water power harnessed by many of the mills, a number of proprietors installed dynamos and began the limited production of electricity. Contracts were signed with city councils for providing lighting services for the towns. In 1899 S. F. Gilman, owner of the Neligh Mill, decided to install electric lights in his mill. After being encouraged by the local citizens, he also began generating electricity for the townspeople. Mill employees began stringing electrical lines and wiring houses, stores, and streets for lights. In 1919 the DeWitt Mill constructed a small hydro-electric power plant to supply power for its own use as well as for the town of DeWitt, one-half mile away. Many local mills also pumped water for the city waterworks. As a result, early in the twentieth century flour mills doubled as the city utilities for many Nebraska towns. The production of electrical power was a lucrative sideline to a mill's business. However, as the twentieth century advanced, an increasing demand for electricity brought

problems to those mill companies. Managers found it was difficult to operate both businesses simultaneously and eventually sold out their electrical interests to power companies.

The twentieth century brought another change to flour milling in Nebraska, the elimination of the small mills and the enlargement of the remaining plants. The decline of the small mill is attributed to three causes. First, there began a demand by housewives and bakeries for a uniform flour. This was a result of the blending of different types of wheat from a large area by large mills to make flour. The smaller mills could only use the wheat at hand which tended to vary in quality from year to year. Second was the general advantage of large scale production in buying quantities of wheat and of increased milling production by the larger mills. Third, because of excessive costs of new milling machinery, the small mill could not keep pace with new milling methods. With those three forces working against them, the small mills could not compete, and they gradually began to close down operations. By 1931 the number of operating mills declined to 81 in Nebraska.

The above reasons plus several years of drouth conditions and the disastrous years of the Depression greatly took their toll on the small mills. The number of mills continued to drop rapidly

through the 1940s and 1950s to 20 in 1958. Today Nebraska has only five operating mills producing flour, and four of them are large-scale plants with daily production equalling that of dozens of nineteenth century mills.

The small flour mill was a part of the Nebraska scene that has virtually disappeared. After operations ceased, most mills were eventually torn down or destroyed by fire. The mill sites were completely leveled for farming or other industrial purposes or obliterated by flooding. Out of the hundreds of mill buildings that once stood in the state, less than 40 can be seen today; some of them are completely neglected, but others are still in use as feed mills grinding grain into livestock feeds. Two of the surviving mills are preserved by the state as historical sites. The Champion Mill in the southwestern part of Nebraska is maintained as a State Historical Park. At the Neligh Mills Historical Site in Neligh the old mill with all its milling machinery intact is operated as a branch museum of the Nebraska State Historical Society. These old mills are preserved relics of a bygone era that were replaced by changing times and relentless progress.

SUGGESTED READING

A. T. Andreas, "History of the State of Nebraska," 1882, Unigraphic Reprint, 1975.

J. H. Campbell, Unpublished paper on the early history of milling in Nebraska, typescript, Nebraska State Historical Society.

A. Croft, "The Flour Milling Industry in Nebraska," Nebraska Studies in Business, No. 23, Extension Division, University of Nebraska, 1929.

Robert M. Frame, "Mills, Machines and Millers," Minnesota History, Vol. 46, No. 4 (Winter 1978).

"The Saga of the Flour Mills," Historical News, Adams County Historical Society, Vol. II, No. 3 (March 1978).

Charles B. Kuhlmann, "The Development of the Flour Milling Industry in the United States," 1929 (Houghton Mifflin Co.: Boston and New York).

"Mills in Thayer County," Museum Muse, Thayer County Historical Society, Vol. I, No. 1 (Winter 1975).

Old Mill News, Publication of the Society for the Preservation of Old Mills, Wiscasset, Maine.

Herman Steen, "Flour Milling in America," 1963 (Denison & Co.: Minneapolis).

Jacob A. Swisher, "Iowa: Land of Many Mills," 1940 (Iowa State Historical Society: Iowa City).

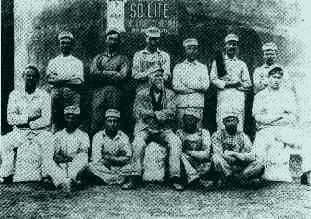

The Crete Mills, in its day one of the largest flour mills in the

state.

A Danish immigrant built this wind-

powered grist mill near Boelus.