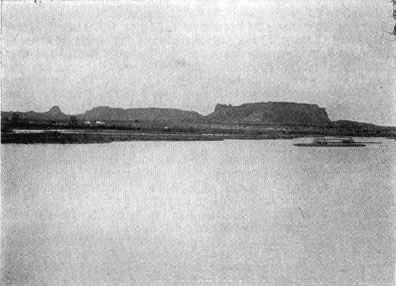

Historic Scotts Bluffs, Overlooking North Platte River chased as artificial fertilizer would cost $9.59, while each ton of corn sold has removed constituents worth $8.60. |

![]()

![]()

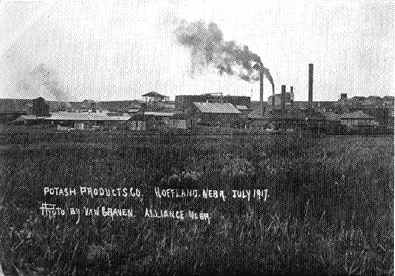

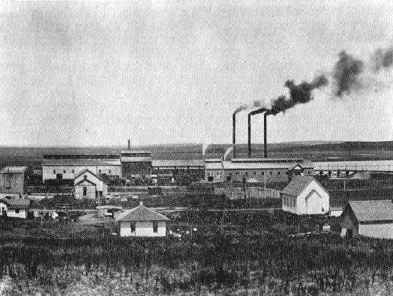

NEBRASKA'S POTASH INDUSTRY So rapid and so marvelous has been the development of the potash industry in Nebraska that it is not possible to give its full particulars within the limit of this publication. The Department of Publicity has published a separate bulletin dealing with the industry, which will be furnished to interested parties upon application. Four years ago not a pound of potash was produced in Nebraska, and the potash production of the entire republic represented less than 5 per cent of its consumption. Nearly 90 per cent of the potash consumed in the United States prior to the beginning of the war was imported from Germany. With the outbreak of the war and the consequent stoppage of potash importations, American consumers cast about for a local supply, and investigators were set to work all over the country. Then it was that potash was discovered in paying quantities in the waters of certain alkali lakes of northwestern Nebraska, notably in Sheridan and Box Butte counties. Others are located in Cherry, Garden and Morrill counties. The potash is extracted from the water of these alkali lakes by reduction. In homely phrase it is "boiled down," much after the manner of making maple sugar. The alkali water is pumped from the lakes to reduction plants located upon the railroad. There are now four huge reduction plants in operation, with three more building and several others planned. The four going plants are producing an average of 100 tons per day each. One plant now under con- |

![]()

|

|

|

© 2002 for the NEGenWeb Project by Pam Rietsch, Ted & Carole Miller