NEW PROCESS OF MAKING STAINED-GLASS WINDOWS

In a short article of this description, it is possible to give only the bare outlines of the art of making stained-glass windows. To begin at the beginning, when the exact shape and subject of a window is decided upon, a water color sketch is prepared to scale, and then the working drawings and cartoon in full size are made. The drawings are done either in monochrome, charcoal, crayon, pencil, or bister, in wash or in color or pastel, according to the taste of the artist.

| by courtesy of the

American Art Glass Co., of Chicago. |

The lead glazing lines are usually shown on the drawing, and for the guidance of the glass cutter a tracing of these lines is made on linen. Possibly, the most important, and certainly one of the most delicate functions in the making of a window, now follows: that of choosing the glass itself, for on this depends to a great extent the final artistic results, as will be presently explained. The artist stands by the cutter and chooses each tint, each sheet, and even indicates the particular part of each sheet most suitable for his purpose. For the color is not always even throughout the glass. What to an inexperienced eye looks like a flaw, a splash of different color, or a mass of air bubbles, is produced intentionally in the manufacture of the glass, and eventually adds to the beauty of the window. When the various pieces are chosen, they are cut to shape on the linen tracing. A tracer now marks on the pieces of glass the main lines of the artist's drawing. It is here that one may point out why stress is laid on the importance of the artist choosing his own glass, and not leaving it to the cutter.

A prevalent idea is that a stained glass window is produced by painting white or ordinary glass with various colors, but it is not so. It is in reality a Mosaic of colored glass, shaped by a pigment of one color only, and, with the exception of what is called staining, which will be presently explained, the color of the glass is in no way changed. The pigment used is chocolate-brown in color, and is made of the same earths as the glass itself, with some iron or copper added to give opacity.

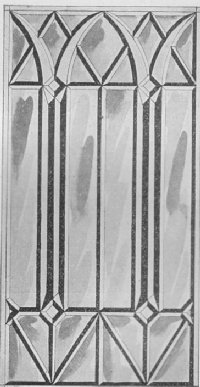

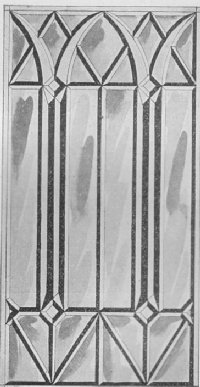

| By courtesy of the American Art Glass Co., of Chicago

Stained class window—representing a hunting scene. |

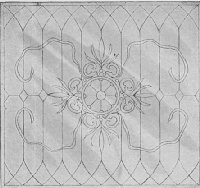

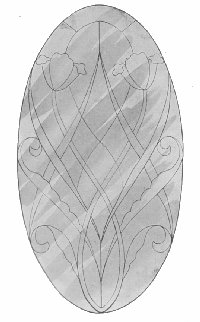

The next process is to stick onto a sheet of plate glass, with hot wax, all pieces, placed in their proper order and position and the whole is then covered with a fairly thick pigment, and, while still wet, stippled to let the light through. When the pigment has dried, the lights and half tones are picked out and brushed away, here and there a shadow is strengthened with more pigment, and the work is ready for diapering and staining. The diapers, or patterns, are either painted on in thick opaque lines, or the existing paint is etched out with points, to the required design (see illustration). Staining is painting the back of such portions of glass as may seem desirable with nitrate of silver, which, when sufficiently heated, changes to a brilliant yellow. It can be so manipulated as to give shades from pale lemon to deepest orange.

The pieces of glass are now all dismounted and carefully laid in flat iron trays, the bottom of which contains a layer of white dry powder; the glass is so arranged that no two pieces touch. The trays are then placed in a kiln heated by powerful Bunsen burners, gradually brought to heat and as gradually cooled. The pigment which, as was pointed out, is made of the same earths as the glass on which it is painted, has become, by firing, part and parcel of the glass itself; it is no longer paint, but actual glass.

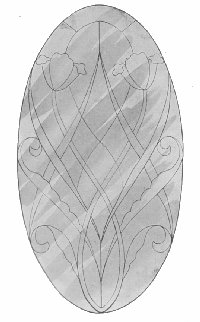

| By courtesy of the American

Art Glass Co., of Chicago.

Artistic window. |

It is now ready for the glazier who, by means of the design or cartoon, puts the different pieces in their proper places, and joins them together by means of grooved leads, and solder. Around the outside edge of the design, in order to bind the whole firmly together, is fixed a stronger piece of lead than that used to join the pieces of glass.

Now follows a very dirty process-that of making the window proof against the weather. This is done by rubbing under the leads a cement made of whiting, oil, etc. The whole window on one side is smeared with this, but it is eventually all cleaned off, leaving a deposit under the leads which makes it water tight. Again the glazier takes it in hand and solders onto the lead cross-bars of galvanized iron at proper intervals. It is now ready for setting.

The stone mullions of a window to be fitted with stained glass are grooved on one side deeper than on the other. The glass is slipped into the deeper groove first and then pulled back into the shallow one in the mullion opposite. The iron bars, called tee bars, are set into the stone on each side of the window holding the glass in place. The space between the outer lead of the glass and the stone work is now carefully filled in with cement, to prevent the rain beating through, and then the window is complete.

NEW METHODS OF MAKING PORCELAIN

LIQUID AIR—ITS WONDERFUL POWER

Table of Contents

Return to Main Page

© 1998, 2002 by Lynn Waterman

|