TIN-MAKING IN THE TWENTIETH CENTURY

| By courtesy of the Scientific American.

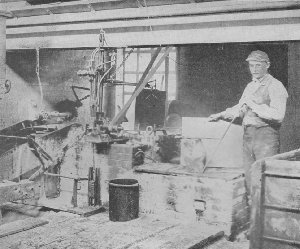

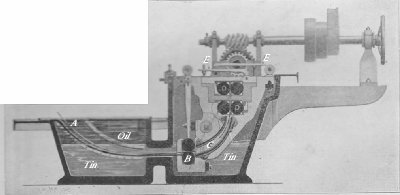

Tinning machine.

With Bennett Magnetic Catcher for removing

tinned plaes as they come from the rolls. |

Originally the method of tinning plates was the simple expedient of dipping them in a bath of molten tin and allowing the surplus metal to drain off; but about thirty or forty years ago, a Mr. Morewood, of South Wales, Great Britain, designed a tinning machine which has since revolutionized the tinning process. The system consists of placing at the surface of the pot a pair of very carefully turned steel rods, which seize the plate as it comes up and roll off the surplus tin, leaving a smooth and even coating of the metal

Even this system has been improved, and to-day the rolls are submerged inside the tinning pots in the hot metal and oil baths, and as the plates pass through, while the coating process is going on, it leaves a uniform coating and a highly polished surface. In the manufacture of high-grade rooting tin, the hand process of dipping is still maintained.

| By courtesy of the Scientific American.

The cutting and doubling shears. |

In this hand-dipping process, known as the—"MF Style," the Plates pass through four or five different pots filled respectively with metal or palm oil. The plates made by this process resist attacks of the atmosphere more thoroughly than plates made in the "coke" tinning process. Recently a new method of finishing has been introduced. In this method, the plates after coming out of the last old-style of "MF," tinning bath, are immersed immediately in an oily substance, the temperature of which is below the melting point of the coating metal, and an instantaneous and uniform settling of the coating metal is thereby effected on all parts of the sheets alike.

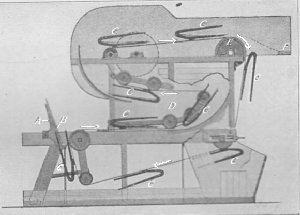

| By courtesy of the Scientific American.

The branner. |

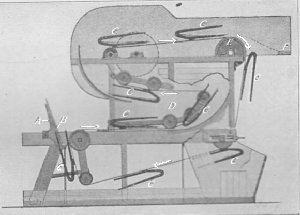

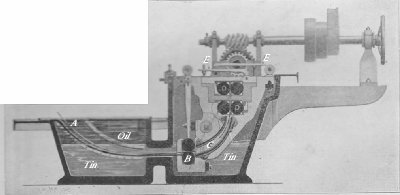

A sectional illustration of a modern tinning machine is herewith given, which shows very clearly its construction. The heavy cast-iron tin pot is carried in a brick setting, and the tin is kept molten by a furnace below the pot. In the bottom of the pot is about 14 inches of the molten tin, and above this on the discharging side are 12 inches of palm oil. The black plate is introduced into the tin pot through the hopper (A). This hopper holds a chemical fluid,the weight of which is less in specific gravity than the molten tin, and which in combination with the tin and iron, causes a galvanic action by which the iron and tin are quickly and thoroughly amalgamated. The tinner pushes the plate downward with a pair of tongs over the curved guide bars until it is seized by the first pair of rolls known as the "feed rolls" marked (B) in the picture. By these it is drawn through the molten tin into the upward curved hopper (C), in which are running two pairs of rolls (D D). The top pair is partly visible and partly immersed in the palm oil which covers the tin on this side of the machine. These rolls are held suspended in a machine frame and are regulated by means of screw-adjusted springs (E E). Upon the adjustment depends the thickness of the coating of tin given to the plate.

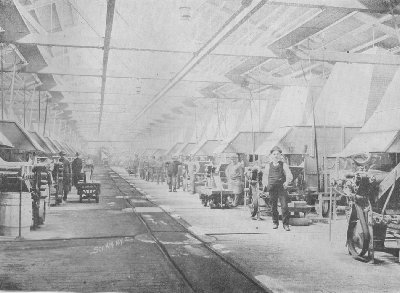

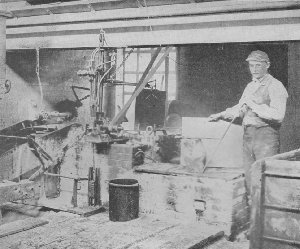

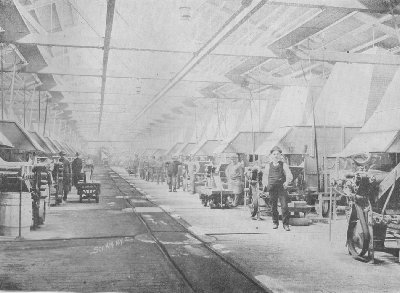

| | The tin house, where block plates are coated with tin. |

| By courtesy of the Scientific American.

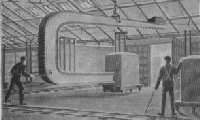

Placing block tin. |

As the plates come out of the rolls they are picked up by a mechanical figure with arms and fingers, which stands above the finishing pot, taking the place of a man. It seizes the plates as they rise through the rolls, swings them sidewise, comes to a stop automatically, drops the plate into a branner, and comes back to its original point of action, repeating the operation in rapid succession.

| By courtesy of the Scientific American.

Sectional view of tinning pot. |

The "Bennett" device for transferring the plates from the tinning pot to the branner consists of a revolving drum with tbe points of contact with the plates magnetized by an electrical connection. As the plates leave the tin pot, they have upon them a thin coating of oil which has to be removed. For this purpose they are put into a branner which is located conveniently at the side of the tinning machine. The branner consists of an inclosed wood and metal box, through which a series of carriers (C) are continually traveling on an endless belt. The plate (B), as it comes from the tinning machine, is placed in a rack (A), which is so located that the plate will be caught up by the traveling racks (C), and by them carried through the machine The interior of the branner is filled with bran and slack lime and as the carrier, travels, it forces the plate through the bran and lime, which cleans off the deposit of palm oil. After the plate has passed through, it drops into what is known as the "duster," where it is passed slowly through a rapidly revolving pair of sheep-covered rollers, which clean off the residue of the palm oil and impart a finishing touch or polish to the plate. There are three of these sheepskin rollers and by the time the plate has passed through the set, it shows the beautiful finish for which tin plate is noted.

SUBMARINE NAVIGATION SCORES NEW TRIUMPHS

A TELEGRAPH MACHINE THAT PRINTS

Table of Contents

Return to Main Page

© 1998, 2002 by Lynn Waterman

|