|

Among the forces that have worked for progress in civilization, none is of greater importance, and yet is more misunderstood, than the modern newspaper. In point of both literary and mechanical perfection, the American daily paper stands supreme. Not only does the metropolitan paper of the United States excel its foreign contemporaries in both bulk and circulation, but it is almost entirely free from the blot of subsidy which smirches so many papers in Europe. Being untrammeled by any but self-imposed checks or hindrances, the American daily is the best exponent of the freedom of the press, and in its fearless attitude in all matters, serves the public with a unique and honest loyalty.

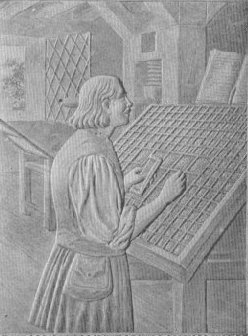

For convenience a business-like newspaper plant is divided into a number of departments, usually as follows, editorial, circulation, advertising, general business, and mechanical. Each of these divisions is in charge of a superintendent, whose duty it is to see that the work of his department goes on with the utmost precision and accuracy. These superintendents in turn confer with each other or are instructed by a general manager, as to that ultimate combination of their forces which produces a perfect newspaper. About 600 people constitute the working force of the metropolitan daily. From start to finish, from office boy to publisher, speed is a requisite. This may be understood when it is known that from the moment the gathering of a day's news begins, until it is printed by the half million copies, and is speeding on its way, by fast mail, to be read by millions, but from six to twelve hours elapse. Let us note the process by which news is picked up and made of commercial value. At the head of the editorial department stands the managing editor, who is responsible for his department to the editor-in-chief and publisher, and to him are responsible the numerous city, associate and sub-editors, and reporters. In general, each of the staffs of a paper is made up of over twenty-five men. Those whose work it is to issue the evening editions come to work before seven o'clock in the morning, relieving men already on duty. Until the last regular evening edition is printed and away, these men are on duty. Overlapping them and coming to work about noon, is the staff of men who issue the following morning's edition While following upon this other staff, comes the third force near midnight, working until relieved by the next day's shift. Each of these staffs is divided in such a manner as most effectually to "cover" the news of the world, and to write and prepare all reading matter, aside from advertisements, that appear in the paper. In order to do this, a number of men are assigned to take care of all the news in certain "departments," such as finance, music, the drama, railroads, politics, leading editorials, the funny column, etc. The routine news of the days is gathered in two ways—that from out of town by mail or telegraph and from special news bureausand correspondents, and the city news, through a corps of local reporters. The former work is under the care generally of the telegraph editor, and the latter, under the city editor. Telegraph news, while not always as interesting and valuable as important local news, yet plays a great part in every paper and relatively costs as much, and frequently more, than city news. The telegraph editor is assisted by several experienced men called copy readers. Since practically all the matter in the telegraph department comes to hand in written form, the duty of these men is principally that of reading it to see that the matter conforms to the general policy of the paper, and to correct any superficial errors. These men also write the large headings for the telegraph news. While the work of editing telegraph "copy" in a newspaper office is something of an easy task, the gathering of this news has reached such a stage of perfection that it may be truly called marvelous. In the main most papers rely upon some news bureau for their out-of-town service. Large papers, however, retain correspondents in many cities (frequently employes of other papers), who gather special items not carried by the bureaus. These correspondents are in constant touch with the paper by mail and telegraph, and aside from a few representatives in very important cities, are paid according to the amount of news printed. So intricate is the business of a well equipped news bureau, that it will be worth while briefly to describe the most important one of the kind, The Associated Press. This association is a corporation, not for profit, and consists of a mutual organization of over 600 of the most influential papers of the country. Its object is to gather the news of the whole world, and to serve its associated members therewith. In every large city in the world this organization is represented by an experienced newspaper man, whose duty it is to gather news worthy of national notice in the United States. Leased telegraph wire is spread across the country in every direction, connecting the principal offices of this organization. Special service is secured from the world's greatest cables. In times of storm, when wires are damaged, the first ones repaired are put in the service of this company. Every effort is made to circumvent time. The service of foreign news bureaus is secured to amplify the work of special correspondence. Thus if a queen dies at Windsor, a king is crowned at London, a new dictator assumes power in one of the Latin-American states, or a tribe of African savages swoops down upon a band of explorers, the news is flashed almost instantly to every newspaper in the association and shortly after appears in printed form for the edification of newspaper subscribers. In smaller cities this news is taken directly from the telegraph instrument by an expert operator, or is served to the newspaper as messages from one of the telegraph companies .In the large cities, where a number of papers are served, the association employs a staff large enough to supply each paper with type-written manuscript. This is usually sent by pneumatic tubes which run underground long distances, and connect the several newspaper offices. The gathering of local news devolves upon the city editor and his corps of reporters. By a simple method of keeping clippings of all notices of important events, to develop, and by carefully tracing down every clew that may lead to news, the gathering of actual happenings of importance in the way of news is reduced almost to clockwork precision. Every man connected with a newspaper is always on the alert for news. The reporters are assigned regularly to certain districts to gather whatever turns up in them. Police reporters are detailed to watch all accidents, crimes, fires, etc., that are reported at police stations. The society department keeps close touch with events of social importance. As in the telegraph news department, there is also a city news bureau in every large city. This bureau has a large corps of men covering routine work, such as courts, police stations city, county and state offices, etc. Thus it is that all papers print, practically, all the news worth printing. Of course, a certain paper, through the large acquaintance of its best men, may now and then secure exclusive news, called a "scoop," but in the long run, one paper prints as many exclusive items as another. Of the newspaper man, himself, it may be said that he is essentially a worker. All sorts of ideas and things are material for him to work upon. His occupation is to him the breath of life. Above all, to succeed, this man must use his every opportunity to the best advantage. To the person who knows nothing of his labors, he appears simply as the genial critic, editor or reporter, with something of a halo about him, denoting that he lives a life free from care and always to be envied. While there are phases of this sort in the life of the newspaper writer, they are exceptional, and the true basis upon which such men build their success is strenuous exertion. From beginning to end of his work day, he must be constantly on the alert for information that may develop into a "story" for his "sheet." True, nowadays, the management of a great newspaper is so methodical that a great deal of the work of the reporter or editor is laid out for him by men in higher authority. Yet, every moment there is some call upon even the youngest of the craft to exercise judgment and caution and a discrimination that is not often necessary in other callings. To the powers that be in the realms of news, there is no such word as fail. If a rival journal has a piece of news exclusively, some one is responsible for its absence from your paper. It does not matter how many exclusive "stories" a man may deliver, how many "scoops" he may secure for his paper, if he is beaten, they count for naught. If he cannot do as well always as men on rival papers, he will lose his position. And, further, the efficient newspaper worker must have perception and adaptability to handle a piece of news when be hears it. The well-equipped man is he who can write intelligently of a technical legal case as readily as of a midnight fire, of things financial with as much facility as of social matter. He must be able to grasp instantly the essential details of any occurrence that may be of value as news. Such a man has a smattering of legal knowledge, of the fine arts, of medicine, to say nothing of the intricate mazes of politics and political jobbery, of the wickedness of the under world and a hundred and one other phases of human action. The actual course of a news story from the moment of the happening to the time it appears in print is something of a dramatic affair. If it is a big fire, when the fire alarm sounds on the special bell in the newspaper office, the city editor locates the conflagration and dispatches from one to ten men, including artists and photographers, to the scene. Generally these work under the direction of one man. Every detail possible is secured. The "office" is informed every few moments by telephone how the fire is progressing, and whether people are being burned or saved, etc. If the hour is late and occasions extreme haste, one man will telephone a connected story of the event to his office, and there it is amplified by an inside man. Pictures are taken and hurried back to headquarters for engraving. If the story, instead of being common to other papers, is to appear exclusively in one paper, great secrecy is maintained. For instance, the writer overhears in a popular Chicago café, shortly after midnight, a conversation between two army officers about the suicide of a well-known military man at a fashionable hotel, on the eve of his wedding. Such news is "hot," and if true, would possibly be exclusive. Every effort is made to obtain the facts without arousing suspicion and the next morning rival newspapers are filled with envy over a great "scoop." After the "copy" of a newspaper "story" has been prepared by the reporter it generally passes through the hands of the city editor or one of his principal assistants, who judges of its news value in order to decide how important a position it shall hold in the printed paper. From him it is turned over to the copy readers, whose duty it is to correct all errors due to haste-for haste is the one great requisite in newspaper work. They also write the large headings and intersperse sub-headings throughout the article. From the copy readers' desk the story travels to the typesetter, thence to the proofreader and back, in the shape of printed proof, to the editors and copy readers, who watch for errors which the proofreader may have overlooked. The course of the passage of the story through other processes will be found farther on, in the description of the other departments of the newspaper plant. The composing room is the place where the typesetter, busy amid the hum of intricate machinery puts into print the articles prepared by the advertising and editorial departments. The work done in setting the big display advertisements, which bring wealth to a newspaper, is done in much the same manner that typesetting was done years ago—by hand. This also is the case with most of the big headings of news articles. The setting of small advertisements and of the body of the paper is done, however, by machinery. The linotype machine which, as its name indicates, sets a line of type by machinery is one of the greatest inventions of the age. Its basic features were developed by Mergenthaler. This machine does the work of many men, and with such speed and accuracy that it is worthy of special notice. It has the appearance of a gigantic typewriter, and has for its main principle the automatic dropping of tiny brass molds for certain letters and figures, when certain keys are depressed. These molds are called matrices, and when a line of them has been set, they are flooded by a combination of molten lead and zinc, thus forming a line of type.

After an article or advertisement has been set up in type, it is hurried over to the "form" or "make-up" table, where it is assigned its particular place in the page of type, is locked up in a great chase, and is sent to be stereotyped preparatory to going on the press. The stereotype department is the outcome of the necessity for rapid printing on cylinder presses. When the old-style hand or flat presses are used, type is frequently used just as it is set. Where newspapers, however, are turned out by the half million copies daily, another method is necessary. As soon as the form of a page of type is delivered to the stereotype department, it is the duty of the workers there to cast a duplicate of it in type metal, but in the shape of a half cylinder. This shape is needed in order to fit on the cylinder rollers of the steam printing presses. The method of making this plate necessitates first the making of a mold which can be bent. This is done by taking an impression of the form in something that resembles papier macb6. Thin layers of prepared tissue paper, with a sprinkling of a floury preparation between them, are placed on the page of type. Then the whole form is run through heavy steam rollers. This presses the paper well down into all the indentations of the type or illustrations in the page. In turn, this is run into a steam chest, where, in a very short time, the preparation is baked stiff. When the mold is removed, it resembless heavy pasteboard, and is the exact facsimile of the page of type. This matrix can be bent readily and placed within a cylindrical chamber, when it is at once flooded with type metal. Almost before the metal is cool enough to have congealed, the stereotypers have opened the molding chamber and have placed the semi-cylinder or plate upon an apparatus where all the imperfections may be chiseled out and the rough edges planed off. This work is so rapid that in a well-ordered department the plates are delivered hot to the press room. Different plants use somewhat different methods, some sending the plates by elevators down to the press room, and some of them being located in the basement of the building adjoining the press room, receive the type forms from the composing room, and send them back by elevator. Everything so far in the passage of the newspaper story from reporter to pressman has worked on rush orders and on schedule time. This is necessitated because the presses must be started at just the same moment every day. Great newspapers have subscription lists containing names of readers hundreds of miles from the city of printing. The papers to these readers must be sent over certain routes by fast mail trains, and to miss a train means that a rival newspaper will be read in many a town the next day, to the exclusion of its competitor. Thus in the editorial room an hour is set, a "dead line,", so to speak, after which nothing can be written which will appear in regular editions of the paper. So is it with the composing room. Certain pages must "go down" to the stereotype room at certain specified times. The whole process from writer to press in rush times is frequently less than half an hour, but this is not the constant speed of the plant. Now, when the stereotyped plates are received at the press room the bustle begins in the great department of steam, machinery and noise. With almost lightning-like rapidity, the plates are clamped two on a cylinder of a press. The size of the paper to be printed regulates the speed of the press, as well as the number of cylinders to be used. Thus a great 20 or 24-page paper, coming from one press, means a dozen cylinders whirling. Before the cylinders have been clamped into place, orders have been issued as to the size of the paper. Great rolls of paper, on spindles like gigantic spools, have been rolled into place on traveling cranes, and grouped about the presses, ready for immediate use. Some of them are already in place in the presses, like several spools of thread in a sewing machine. When the plates are all in order a signal is given , every man gets out of the way of the danger of crushed arms or legs in the immense rollers, and the steam is turned on by a great lever. The paper is fed from the rolls on the spindles down between the revolving cylinders and smooth steel rolls. This causes the impression, and prints the newspaper. In guiding the paper through the rolls cloth tapes are necessary, to prevent the paper from slipping. After the paper is printed it passes over certain knives, paste brushes and folders, which sever the paper from the continuous roll, paste the leaves in position, when this is necessary, and fold the paper ready for the street. All this is done so rapidly that it can be counted only by machinery. Papers with only a few pages can be run out, ready for delivery, at the astounding rate of 48,000 an hour. An order was recently placed with R. Hoe & Co. for seven double octuple presses, equal to 28 quadruple machines, or 112 ordinary single-roll presses. These, will print on eight rolls of paper the width of four newspaper pages, and when running to the full capacity the output from each will be equivalent to 200,000 eight-page sheets per hour. Eighteen hundred feet of printed webs of paper will pass through one of these machines every minute. The 16-plate cylinders each carry eight stereotyped plates, and 64 pages can be printed at will, in black or in colors. From the press room to the reader is comparatively as rapid as the other operations of the plant. Bundles, of several hundred at a time, are seized from the presses and hurried by automatic devices—little traveling elevators and cars—to the delivery room. Here crowds of newsboys and delivery men are eager to speed them on their way. Those papers that are to be read in the city of publication are hurried by fast wagons, elevated trains and street cars to every section, business or residential, of the great metropolis. On the morning newspaper this is done while the greater portion of the town still sleeps. The papers that are to be sent to suburban villages and distant towns take another course. The circulation department has already had prepared lists of all readers and dealers who get the paper. These lists indicate the post office address of subscribers, number of papers subscribed for and date of expiration of subscription. Long before the, paper is printed, expert "mailers" have deftly pasted the little yellow slips from these lists on the wrappers in which the papers are to be mailed. This operation is done by means of a little machine called the "mailer," which can be used by one hand and made to paste the slips very quickly. When the papers are received from the press room, the workmen in the mailing room seize bundles of them, count them out accurately and swiftly, wrap them, bundle them into United States mail bags, and hurry them off in wagons to catch the fast mail trains. One of the great adjuncts to the latter-day journal is its illustrative features. A paper that does not print pictures, and many of them, is playing, as a rule, a losing game. This necessitates a photographic art and an engraving department. When an artist or photographer returns from an assignment to secure a certain picture for the columns of the paper, great speed is generally required. If it is a sketch, the artist has been working out his idea on the way to the office, in his cab or in the street car. In his studio, he rapidly makes the drawing of fire, wreck or person. Fine white Bristol board is used, and India ink leaves the lines black, for the engraver. The photographer, in case a photograph is to be used, has hurriedly developed his plate, and from it has had a picture printed on sensitized paper. Perhaps the artist must retouch this picture or redraw its fainter lines in ink. This is hurriedly done and the results are taken to the engraver. Here either of two methods may be used. One is the half-tone process, which is used principally for photographs of persons, and the other is the zinc-line etching for black and white drawings, sketched by artists. In the latter method a "wet-plate" photograph is made of the artist's work, possibly of several sketches at once. This wet-plate photograph is much like the ordinary dry plate negative of the snap-shot photograph camera, excepting that the gelatine with which the glass is coated is yet wet when the picture is exposed. This gelatine is developed by ordinary photographic methods. Then the gelatine of several pictures is removed from the first glass used and pasted on heavy plate glass, a number of pictures in a group. After these have been dried hard by heat from a gas stove, this plate of pictures is enclosed in a frame with a sheet of zinc, sensitized after the manner of photographic paper. The plate is now exposed to the glare of an arc light. The sensitized zinc receives the impression from the light and negative, and after it has been developed and eaten down by acids, and by machinery which routs out imperfections, we have engravings of the pictures first drawn or photographed, now ready for mounting on metal bases for the printed page. In half-tone work, the process is similar, but when the photographs or artist's drawings are being photographed, fine screens intervene between the plate and the pictures, in order to give the mellowed shadings of the finer engravings. Besides the departments already described there are the distinctively business offices, without which no paper can thrive. The circulation department canvasses, schemes and plots to secure a large number of readers for the paper. All sorts of devices are made use of. Prizes are offered, books and pictures are given away, and great quantities of advertising matter are sent out by hand and by mail. Men are paid fabulous salaries for ideas to swell the circulation lists.

The expenses of running a newspaper plant are very great. It should be known that hardly any large paper ever makes any money from its subscription list. The paper on which the journal is printed nearly always costs more than the printed papers bring in return. It is the advertising which counts, and the circulation list counts in turn only as it can give greater publicity to the advertising and thus serve as the means of securing much advertising matter and high advertising rates. It is figured, generally, that if a plant can deliver its publication without losing money on its selling price, it is in excellent condition. This, of course, is seldom the case with great Sunday papers, with their 50 and 60 pages of expensively-written and illustrated articles. THE "SOO'S" GREAT POWER CANAL |