|

In this day of progress, when everything in nature is being reproduced by man, it is little wonder that the demand for ice has resulted in the discovery of methods of manufacturing it. While the natural ice crop is still depended upon for the greater portion of the civilized world's ice supply, yet so far have the devices for ice making been perfected that artificial ice is now a strong competitor of the natural product in all large cities.

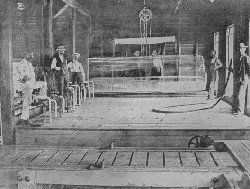

The principle upon which artificial ice is made and refrigeration produced is that of absorption of the heat in the surrounding atmosphere. This is done in a number of ways. In making liquid air, which is the coldest substance known, the process consists in making use of the law of nature which insists that compressing a gas warms it and then liberating it quickly cools it. Thus air is compressed and all the surplus warmth taken from it by spraying the pipes which contain it with cold water. Then when this cool and compressed air is liberated it expands with such rapidity that the warmth in the surrounding atmosphere is absorbed and a great cold is produced. This same principle is applied in a little different manner in the practical use of ammonia in making ice for commercial use. The idea is that anhydrous ammonia, which freezes at 32 degrees Fahrenheit--so cold is it--upon being brought in contact with water, will take from the water its warmth. The ammonia method is the one most universally in use both in making cakes of ice and in keeping down the temperatures of cold storage warehouses. One method for using ammonia is called the can system. In its use, water in cans the size of the cakes of ice to be manufactured, is exposed to the ammonia circulating through coils of pipe laid in a tank of salt water. The ammonia absorbs the heat from the salt water and the salt water in turn freezes the water in the cans by absorbing its heat. Where storage rooms are to be cooled with making ice, the ammonia is pumped through pipes which run about the rooms and thus absorb the warmth in the air at first hand. In this process the air around the pipes, of course, is the coldest in the room. Thus the moisture that may be contained in the air nearest the pipes will be precipitated on the outside of the ammonia pipes in the form of thick snow ice. One of the most efficient methods for ice manufacture is called the Holden system. By its use ice can be made for 50 cents a ton in a very small plant as against a cost by the can system of nearly $2 a ton. The plant necessary in this system consists of a device for circulating the ammonia without loss and the ice machine. The former consists of three vertical pipes, 12 inches in diameter, and 40 feet high. These are called the still, the absorber and the condenser. Besides these there are two shorter pipes called the interchanger and the cooler, while an ammonia pump furnishes the power for circulating the ammonia. Strong ammonia liquor of 32 degrees, Bane intensity, is pumped through the interchanger to the stop of the still. In the interchanger, it is practically heated. In the still, which is a device full of pipes which break up the ammonia into small drops, the ammonia is heated by steam and allowed to trickle down, giving off, the while, a strong ammonia gas. This gas passes out to the top of the absorber which is filled with pipes carrying circulating water. Here the gas is converted into anhydrous ammonia of exceedingly low temperature, and is ready to pass to the ice machine to do its work in the making of ice. The ice machine consists of a hollow cylinder supported by hollow trunnions, the whole affair revolving in a tank of water. The anhydrous gas passing into this cylinder through one trunnion creates a very low temperature which at once takes up the heat that is in the tank of water. All the time the cylinder is revolving a thin film of ammonia clings to its inside walls. On the outside the water changes to a coating of ice. This is removed by knives which scrape off the ice in the form of "spawls." These "spawls" naturally rise to the top of the water in the tank, and as they accumulate, are conveyed by a screw propeller to great presses. These presses are hydraulic and are so arranged that all the water and air which is carried to them with the "sprawls" of ice are squeezed out, thus leaving blocks of ice clear and solid as crystal. After the ammonia gas has done its work, it passes out through the other trunnion of the ice cylinder, finds its way through the absorber, receiver, etc., and, mixing with the weaker ammonia water of the first operations, begins its journey again with the pump to the still. A SUBSTITUTE FOR IRON IN BUILDING |