SUBMARINE TELEGRAPHY

Its Debt to Sir William Thomson—The Laying of a Cable— Various Inventions.

YOU might fancy that, once telegraphy had been proved a success on land, the submarine cable would have been a simple development. After all, it is only a matter of sufficiently insulating the wire, then laying it on the bottom of the sea.

That is just what the electricians of Morse’s time thought, but they soon found that the matter was not so simple as it seemed. The fact is that a long cable, with a metallic core and insulating sheath and salt water outside, acts like a gigantic Leyden jar or condenser. The current, flowing along the copper core, induces in the water opposing currents, and these reduce the speed of transmission. To begin with, the currents must be weak, for if they are too strong they will ruin the cable, as happened in the case of the first transatlantic cable laid in 1858. This lasted for twenty-three days only, then went "dead."

It was a terrible blow to Cyrus Field and the other promoters, for the expense had been enormous. Now it seemed as though the money had been utterly wasted, and that it was impossible to establish electrical communication across the breadth of the Atlantic.

But there was a man living who thought otherwise. This was William—afterward Sir William—Thomson, one of the greatest scientists of the nineteenth century. William Thomson was born in 1824 at Belfast in Ireland; but while still quite a small boy his father was appointed Professor of Mathematics at Glasgow University, and it was at this University that young Thomson received his early education, and where he first became interested in electricity.

Thomson had foreseen the difficulties attending the sending of messages through nearly two thousand miles of insulated cable, and he realized that what was required was a method quite different from that used on land lines. The current sent could be but tiny, and his idea was to make it visible. It was for this purpose that he invented his mirror galvanometer. Before Thomson’s day, Oersted, the famous Danish philosopher, had made the discovery that when a current is sent along a wire in the neighborhood of a freely suspended magnetic needle, the needle will be deflected, and its new position will be right or left according to the sort of current sent through the wire. More than this, the amount of deflection will depend upon the strength of the current.

It was by taking advantage of these discoveries that Thomson invented his mirror or reflecting galvanometer. The wire through which the current to be measured is made to pass consists of many turns of very thin insulated copper wire, forming a hollow coil, in the heart of which a tiny needle is suspended by a gossamer thread of floss silk. The magnets carry a wee circular mirror, the whole arrangement of magnets and mirror being no longer than four or five of these printed letters which you see before you. A beam of light is thrown from a lamp on to the mirror, and reflected back from the mirror on a graduated scale. The distance to which the reflected beam is moved along the scale measures the strength of the current passing through the coiled wires, and so the resistance of any wire to any particular current can be accurately measured. Also, the mirror galvanometer affords a means of making visible to the operator currents far too feeble to work the ordinary sounder.

The amazing delicacy of Thomson’s apparatus is proved by the fact that when the first Atlantic cable had been successfully laid so little current was required that the cell used for sending the messages was made from a lady’s silver thimble, a bit of zinc, and a few drops of sulphuric acid. Yet this incredibly tiny current after crossing the whole Atlantic was easily visible by means of Thomson’s galvanometer.

The first submarine cable was laid between England and France in the year 1850, and two years later England and Ireland were connected. It was in 1857 that the first attempt was made to lay a cable across the Atlantic, but the attempt ended in failure. The next year a second attempt was made and the story, though it has often been told before, is so interesting that it is worth repeating. In June, 1858, the Niagara and the Agamemnon, the latter a warship lent by the British Government, sailed, each having aboard one-half of the great Atlantic cable destined to join the Old World and the New. It was at first intended that the two vessels should proceed to mid-ocean, there splice the cable and steer, one for Newfoundland, the other for Ireland. But this plan was changed, and it was decided that the Niagara should start from the Irish coast westward, accompanied by the other vessels of the fleet, and, when she had finished "paying out" the cable, that the Agamemnon should continue the laying.

Luck was against the expedition from the start. An appalling gale arose, and the Agamemnon was forced to fly before the storm for thirty-six hours. Her coal got adrift, two of her sailors were badly injured and one actually went mad with fright.

Captain Priddle, her commander, managed, however, to weather the hurricane and get his ship to the agreed rendezvous, where he met the Niagara. The splice was made, and the two vessels steamed away, but hardly were they out of sight of each other before the cable snapped. It was fished up, spliced, and the process of laying resumed again and again, but every time with the same ill fortune. The fact was that during the storm the coils of cable aboard the Agamemnon had shifted and become kinked. In the end, having lost three hundred miles of valuable cable in mid-ocean, the expedition was forced to return home.

The managers of the company were not disheartened. More cable was put aboard, and on July 17 a fresh start was made. To the amazement of everybody, on August 5 the Niagara safely arrived in New York, bringing news that the task was safely finished. The excitement was tremendous, and reached its climax when, on August 16, the President of the United States received the first telegraphic message from Queen Victoria.

But this new cable was poorly made, and, as I have explained, would not stand the heavy current that was being forced through it. At the end of twenty-three days it ceased to work, to the bitter disappointment of all concerned. Four hundred messages in all had been sent across it, and it is worth mentioning that one of these sent from the War Office in London to countermand the return of a certain regiment from Canada to England had saved the taxpayers of Great Britain the sum of fifty thousand pounds. In 1865 the Atlantic cable was recovered and repaired, and in 1866 a new cable was laid. This was one thousand eight hundred and ninety-six miles in length and weighed three thousand three hundred tons.

Many inventions besides that of Thomson have gone toward making the deep-sea cable a success. One of these was the adhesive mixture named Chatterton’s Compound. It is made of resin, gutta-percha, and Stockholm tar. It is not only adhesive, but also absolutely waterproof and, into the bargain, a good insulator.

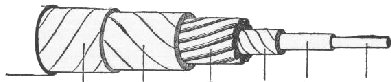

There is perhaps no other article made by man over the manufacture of which more care is taken than a submarine cable. The slightest fault, you will realize, destroys the value of the whole cable. Never was there a better example of a chain being no stronger than its weakest link. All the materials are carefully watched, especially the iron wires used for sheathing, which are tested for stretching, twisting, and breaking strains. As

|

each mile of cable is made and coiled away, its properties are separately chronicled. And even after it is completed the whole cable is electrically tested every day. When finished in the manufactory the cable is coiled in great tanks filled with salt water until it is taken away for laying.

The laying is always a difficult and intricate business, and could not be done but for the skill of numerous inventors. Before the days of steamships it would have been impossible to lay a cable, for in order to do so it is essential that the ship should be independent of wind and weather. The modern cable ship is fitted with screws at either end, so that she can reverse her motion without the need for turning round. She is provided with huge iron tanks for containing the cable and with very special machinery for paying it out and hauling it in. Particularly ingenious is her machinery for taking deep-sea soundings. It was Brooke, an officer of the United States Navy, who invented the modern method of sounding by using a detachable weight, the sinker being left at the bottom, and only a small tube containing a sample of the bottom being hauled up with the line. Later, sounding by means of a wire rope for telegraphic purposes was carried out by Sir William Thomson. The diameter of wire being so much less than that of rope there is less friction, and wire runs out and can be hauled in more rapidly than rope.

Another very ingenious invention for sounding purposes is Siemen’s Bathometer. The bathometer has a dial like that of a barometer. It stands in the captain’s cabin, and indicates by means of a needle the depth of the sea over which the ship is passing. Its action depends on the attraction of the earth upon a column of mercury.

Suppose a cable ship, all loaded up, is properly equipped and manned and ready to begin paying out the cable. The cable cannot, of course, be allowed to run out by its own weight, but must be checked by certain mechanism so that it may pay out evenly. On the other hand, it must not be checked too hard, for if this should occur, it would be very easy to strain or break the cable. It is necessary, therefore, to know exactly what tension or pull there is upon the cable at any time, and for this purpose two inventions are needed.

One is the friction brake first invented by Appold; the other is the dynamometer. The latter consists of three pulleys, two fixed and one a riding pulley. The cable passes over the fixed pulleys and under the riding pulley. The weight of the latter pulls it into a V-shape, and the depth of the V becomes less as the tension on the cable increases. So the speed of the ship can be adjusted to give the right amount of slack. The revolution of the drum of the brake, the strain on the cable, and the number of turns of the ship’s screw are observed the whole time, night as well as day. Down

|

If any "fault" is reported, the ship is instantly stopped, and tests are applied to find where the fault has occurred. So perfect is the modern apparatus that a fault is usually perceived before the faulty length has sunk into the depths. Then the cable is cut, the faulty part removed, a new splice is made, and the laying goes on as before. If it should happen that the faulty part has been laid upon the bottom the "picking up" gear is used, and the cable hauled slowly in by means of a steam winch.

At best, cable laying is a ticklish operation, and in bad weather desperately difficult and even dangerous. In a really bad storm it may become necessary to cut the cable, buoy the end, and leave it until the weather moderates.

Chapter 11

Chapter 9

Table of Contents

Return to Main Page

© 2000, 2001, 2002 by Lynn Waterman