HARNESSING NATURE

Various Sources of Power—The Turbine and the Pelton Water Wheel—The Wasted Wind—Power from the Tides, and Direct Heat from the Sun.

IN Chapter XXVII, something was said of the many valuable materials produced cheaply by the tremendous heat of the electric furnace. Now, while we can obtain electric power by burning coal or oil or gas, a far more economical method of producing it is from water power. Coal represents the locked-up energy of the sunshine of former ages, but in order to use its mechanical energy it must be dug from the earth and baked or burned. Although the stocks of coal hidden in the bosom of the earth are very large, yet they are not endless; in England the shallow deposits have already been worked out and only the deeper ones are now available, and these are naturally more expensive to raise to the surface. Consequently, British coal is already twice its price of a few years ago, and tends to become still more costly.

Water power differs from coal power in that it can never be exhausted so long as rain falls upon the hills and snow upon the mountains, yet up to a comparatively recent date nearly all this wonderful supply of energy has been allowed to run to waste. Not quite all, for the power of falling water has been known to man for thousands of years, and in the East water wheels have been used time out of mind for irrigation purposes. Later on, the water wheel came into use in Europe for grinding corn, for running sawmills, and for other similar purposes, but no inventor of the time was able to solve the problem of constructing a water wheel suited to any but the most moderate power. So when steam power came in, the first thing to be scrapped was the old water wheel,

|

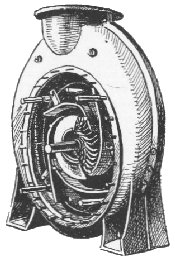

The water is directed upon the blades by guides and is discharged at the center. The wheel is rotated by the endeavors of the water to escape. |

The causes which brought about the return to water power were the inventions of new methods for making use of it, and of these the most important are the turbine and the Pelton water wheel. The turbine was actually invented about the year 1801. Briefly speaking, it is a wheel with thin curved blades enclosed in a casing. The water falls through a conduit called "the penstock", and, entering at the circumference of the casing, is turned upon the blades by guides, and escapes in the center. The movement of the blades rotates a shaft which communicates with a dynamo, as appears in the illustration.

There are many different modifications of the turbine according to the head and weight of water available. Turbines are made with vertical shafts which will work with a head or fall of only three feet, but the horizontal type is used with heads of water exceeding sixteen feet.

The Pelton water wheel was invented by an American carpenter of that name. The water flows from a nozzle against the cuplike blades of the wheel, and so rotates it. Many water wheels of the old type—that is, of the sort you may see in the old-fashioned water mill for grinding corn—were used in the early days of gold mining in

|

Western America. They were employed to obtain power for sluicing the gold-bearing soil from the faces of the cliffs. These old-fashioned wheels, of which many still exist, have buckets or cups on the outer rim of the wheel into which the water pours from above, its weight causing the wheel to revolve.

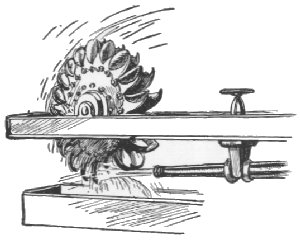

The wheel which Pelton was repairing had gone a little crooked, and Pelton was sharp enough to notice that the jet of water coming from above and falling on one side of the buckets instead of into the middle did not splash and seemed to drive the wheel at increased speed.

The idea came to him to divide the buckets in the middle; and after making a wheel on these lines he found, just as he had expected, that it worked much better than the older form. A glance at the illustration shows the Pelton wheel better than a

|

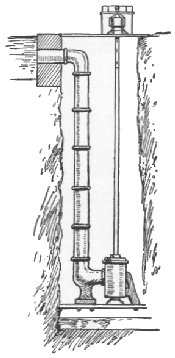

Let us consider just how water power is used with the aid of the turbine—that is, a wheel with curved blades enclosed in a casing. As we all know, the Niagara River is the spout through which the surplus waters of Lake Erie flow into Lake Ontario. The fall at Niagara is 216 feet, and the quantity of water coming over is reckoned at 222,400 cubic feet a second, or nearly a cubic mile in one week. To put it from another point of view, the weight of water falling is twenty-two million tons an hour, or the equivalent of five million horsepower. The first turbines used at Niagara were massively constructed wheels of bronze, each five feet in diameter. They were set at the bottom of a "wheel pit" 140 feet long by 18 feet wide by 178 feet deep.

The water is carried from the main river to the mouth of the wheel pit by a canal two hundred and fifty feet wide and twelve feet deep. Each turbine, of which there are ten, was built to give five thousand horsepower. In order to carry away the water after it had been used, a tunnel was cut one and one-third miles long through the solid rock. This tunnel is nineteen feet wide and twenty-one feet high.

This, however, was only the first of a number of similar installations made on both sides of the Falls; and to-day for over three hundred miles east and west, and more than a hundred miles north and south, electric power from Niagara works great factories, runs railways, lights towns, and does all the work which, in less favored localities, requires the burning of millions of tons of coal.

America’s water power is enormous, and is being constantly developed. England has few such resources, but something is being done to make use of the considerable water power available in the Highlands of Scotland. Italy, being a country with no natural supplies of coal or oil, is entirely dependent upon other sources of power, and is rapidly harnessing every available waterfall. Perhaps because she is so short of fuel, Italy is the first country in the world to make a serious attempt to use the internal heat of the earth.

At Larderello, forty miles southwest of Florence, is an area of two and a half square miles which, for thousands of years, has been avoided by the superstitious peasant. Here jets of steam issue from the earth with queer, whistling noises, and the air is heavy with the reek of sulphur. Some years ago Prince Conti determined to make use of this waste steam and put up an electric generator. It worked excellently, and to-day the towns of Florence and Siena are lighted by volcanic power. A generating plant is being built to increase the output to fifty-five thousand horsepower, and near Naples borings are being made with the object of installing a similar plant, for here is another area which gives out steam.

There are but few places where steam is tapped close enough to the surface to be of use; but happily there is no part of the world where the wind does not blow, and next to water power it is wind power that is most likely to supply man’s need for fresh sources of power.

Over continents and oceans mighty rivers of air sweep unceasingly; but we, living behind walls or in gardens sheltered by trees, are apt to forget these little-used forces.

A wind engine is the most economical of all sources of power. A stationary wind engine needs no crew; it turns itself to face the wind and reefs its own sails when the wind increases in force. It merely needs oiling occasionally, and for the rest looks after itself. What, then, is the disadvantage of this cheapest of servants? It is this: the wind does not always blow. This cessation is quite irregular, and the duration of a calm cannot be foretold. It may last an hour only or it may go on for a week. Yet if the wind is fickle it is not so treacherous as might be supposed. On an average there is always a working wind for half the year, and in open country three hundred feet above sea level there is a wind of ten miles an hour or more for nearly three quarters of the time.

Of late years many improvements have been made in the windmill, and to-day a steel tower with a wheel of sixteen to twenty feet in diameter can be put up fairly cheaply and will do a surprising amount of work. It will pump water, drive a sawmill, churn, crush feed, mix manure, or run an electric-light plant. It will deliver daily ten thousand gallons of water to a height of one hundred feet, and will, at any rate, save the keep of a horse. In America an ever-increasing number of these small steel windmills are being set up, and the number now sold is not much less than ten thousand yearly.

These modern wind engines differ very widely from the old radial-armed windmill with its wooden shutter or canvas sails. In those old-time windmills the sails had to be pushed into the wind by means of a long tiller arm at the base, but this was replaced by the revolving head, which automatically brought the mill into the wind. In the center of the sails was mounted a governor which acted directly on the divisions of the sails, opening or closing them as required. In the new type of steel-tower wind engine the control is effected by the use of a revolving head with a rudder or tail vane, which, if the wind blows too hard, turns the wheel more or less away from it. A new form of windmill was invented by Major Bilau in 1924, which is said to have advantages over any of the older types. Whereas all windmills hitherto have faced the wind, and all subsidiary apparatus, including the vane, have been behind, Bilau’s wheel is on the side of the tower remote from the wind, so that the wind leaving the machine suffers no disturbances. It is free to exert its full "suction" effect. That is the first step toward getting the maximum power out of the wind. He uses only four "wings" in his wheel, instead of six or eight as customary in old types, but the most striking difference is that Bilau’s wind wings are shaped on scientific principles. They are, in fact, exactly the same as aeroplane wings, and for precisely the same purpose—to obtain the maximum "suction" effect. Bilau also provides what would appear to be a perfect automatic regulator.

So it looks as though the world was at the beginning of a new effort to make more use of the neglected wind. Professor Fessenden, a distinguished Canadian, lecturing before the British Association, stated that if windmills were put up along the English cliffs there would be easily obtained enough electric power to run all the railways and manufactories in the country.

Another form of power which is at present even more neglected than that from wind is tide power. There are, it is true, great obstacles in the way of the use of tidal force in most countries, for the rise and fall are not sufficient to give great power without enormous expense. There are, however, certain localities, such as the mouth of the river Severn and the Bay of Fundy on the Nova Scotian coast, where it would be feasible to harness these mighty forces.

In the Bay of Fundy the tide rises and falls no less than forty feet twice a day. Here the tidal race pours out to

|

sea through a narrow gap not more than three miles wide, and careful calculation proves that through this gap two hundred million horsepower runs to waste every day in the year. To utilize this gigantic force would mean the expenditure of millions; but the power obtained would be so tremendous, and therefore so cheap, that it is safe to predict that it will be done.

The French Government is to undertake a tidal-power scheme at Aber Wrach in the département of Finistère in Brittany. It is proposed to erect a barrage 164 yards long and four groups of turbines which will be driven both by the flood and ebb tides. A minimum of 1600 and a maximum of 3200 horsepower will be obtainable.

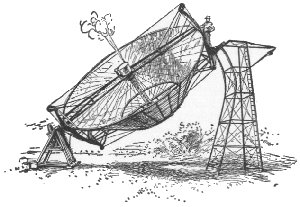

The last source of power which I shall mention is that obtainable from direct solar heat. At South Pasadena in California a ten-horsepower boiler has been working for some years by steam which is raised entirely by sunheat. The apparatus consists of a cone lined with 1700 mirrors, so arranged as to reflect upon a steel tube containing about a hundred gallons of water, and placed in the center of the cone. The cone, driven by clockwork, follows the movement of the sun. The boiler can be used for eight hours on every clear day, and it takes no more than an hour to get up steam, after which the engine works steadily until sunset. It is capable of pumping about fourteen hundred gallons of water in a minute. The cost compares favorably with coal-heated or electrically driven engines. At Meadi, a suburb of Cairo, a complete sun-power plant was set up for working an irrigation plant; but the temperature obtained was so much higher than expected that the zinc boilers, which were similar to those used in California, would not stand the strain. It appears that in any tropical country where fuel costs more than ten shillings a ton sun power could be used with advantage.

Chapter 29

Chapter 27

Table of Contents

Return to Main Page

© 2000, 2001, 2002 by Lynn Waterman