THE HORSE

HE horse must have been one of the first animals subjected to the use of man, but there is no record made of it before the time of Joseph, during the great famine in Egypt, when Joseph exchanged bread for horses. During the exodus horses were used more extensively, and in consequent wars we find the horse used especially by great men and heroes. This noble animal has always been held in high esteem by civilized people. In wars and journeys and exploits, as well as for transports, the horse is of immeasurable value. No people cared for and loved this animal as did the Arabs. The care and breeding of horses was their main occupation, therefore their horses were noted for intelligence, high speed and endurance. The English and American thoroughbred has an infusion of blood of the Arab horse, which has set the price on these animals. Pedigrees were first established by the Arabs.

HE horse must have been one of the first animals subjected to the use of man, but there is no record made of it before the time of Joseph, during the great famine in Egypt, when Joseph exchanged bread for horses. During the exodus horses were used more extensively, and in consequent wars we find the horse used especially by great men and heroes. This noble animal has always been held in high esteem by civilized people. In wars and journeys and exploits, as well as for transports, the horse is of immeasurable value. No people cared for and loved this animal as did the Arabs. The care and breeding of horses was their main occupation, therefore their horses were noted for intelligence, high speed and endurance. The English and American thoroughbred has an infusion of blood of the Arab horse, which has set the price on these animals. Pedigrees were first established by the Arabs.

Each country has its own breed of horses. Horses of a cold climate are smaller in size, as also are the horses of the tropics. The best horses are found in the temperate zone. In Germany the horses are large, well formed and strong.

|

|

The horse in a wild state needs no shoes, the wear and tear that the feet are subjected to while the horse is hunting for his food in a wild country on soft meadows, is just right to keep the hoofs down in a normal condition. But when the horse is in bondage and must serve as a burden-carrying animal, traveling on hard roads or paved streets, the horse must be shod to prevent a foot wear which nature cannot reuperate. Horseshoes were first made of iron in 480 A. D. Before that time, and even after horseshoes have been made of leather and other materials.

|

It is necessary in order to be a successful horse-shoer to know something about the anatomical construction of the feet and legs of the horse. Of course, any little boy can learn the names of the bones and tendons in a horse's foot in an hour, but this does not make a horse-shoer out of him. No board of examiners should allow any horse-shoer to pass an examination merely because he can answer the questions put to him in regard to the anatomy of the horse, for as I have said before, these names are easily learned, but practical

|

It is not my intention to treat on this subject. I could not; first, because there is not room for such a discourse, second, there are numerous books on the subject better than I could write, available to every horse-shoer. I shall only give a few names of such parts of the anatomy as is essential to know. What the horse-shoer wants to know is the parts of the foot connected with the hoof, as his work is confined solely to the foot.

|

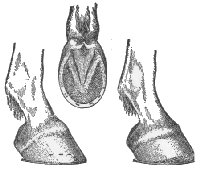

The wall or crust is the horny sheath incasing the end of the foot, in the front and on the sides from the coronet to the ground. It is through this crust the nail is driven, and it is upon this crust the shoe rests. In front it is deepest, towards the quarter and heel it becomes thinner. It is of equal thickness from the upper end to the ground (from top to bottom). The white corored wall is the poorest, while the iron colored wall is the toughest. The growth of the wall is different at different ages. It grows more in a young horse and colt than in an old horse; in a healthy foot and soft, than in a diseased foot and hard. In a young horse the hoof will grow about three inches in a year and even more, while it grows less in an old horse. The wall is fibrous, the fibers going parallel to each other from the coronet to the ground.

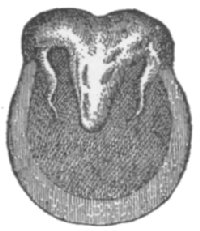

The horny sole is the bottom of the foot. This sole is fibrous like the wall. The sole is thickest at the border, where it connects with the wall, and thinnest at the center. The sole when in a healthy condition scales off in flakes. This scale is a guide to the farrier whereby he can tell how much to pare off. There are different opinions in regard to the paring of the sole, but that is unnecessary, for nature will tell how much to cut off in a healthy foot. In a diseased foot it is different; then the horse-shoer must use his own good judgment. It is, however, in very few cases that the shoer needs to do more than just clean the sole. Nature does the scaling off, or paring business, better than any farrier.

The frog is situated at the heel and back part of the hoof, within the bars; the point extending towards the center of the sole, its base filling up the space left between the inflection of the wall. This body is also fibrous. The frog is very elastic and is evidently designed for contact with the ground, and for the prevention of jars injurious to the limbs.

Coronet is the name of the upper margin of the foot, the place where the hair ceases and the horny hoof begins.

The quarter means a place at the bottom of the wall, say, about one-third the length from the heel towards the toe.

By the bars we mean the horny walls on each side of the frog, commencing at the heel of the wall and extending towards the point of the frog.

Any blacksmith or horse-shoer desiring to study more thoroughly the anatomy of the horse should procure a book treating on this subject.

It is only in exceptional cases that the shoer turns or makes a shoe. The shoes are now already shaped, creased and partly punched, so all that is needed is to weld on the toe calk and shape the heel calks.

Heat the shoe at the toe first, and when hot bend the heels together a little. This is done because the shoes will spread when the toe calk is welded on, and the shoe should not be too wide on the toe, as is mostly the case. If the shoe is narrow at the toe it is easier to fit the same to the foot and get the shoe to fill out on the toe. Many smiths cut too much off from the toe. Before the toe calk is driven onto the shoe bend it a little so as to give it the same curve the shoe has, and the corners of the calk will not stick out over the edge of the shoe. Now place the shoe in the fire, calk up. Heat to a good low welding heat, and use sand for welding compound. Don't take the shoe out of the fire to dip it in the sand, as most shoers do, for you will then cool it off by digging in the cold sand, of which you will get too much on the inner side of the calk. The same will, if allowed to stay, make the calk look rough. You will also have to make a new place for the shoe in the fire, which will take up a good deal of time, as the new place is not at once so hot as the place from which the shoe was taken; besides this, you might tear the calk off and lose it. When hot give a couple of good blows on the calk and then draw it out. Don't hold the heels of the shoe too close to the anvil when you draw out the calk, for if you do the calk will stand under, and it should be at a right angle with the shoe. Do not draw it out too long, as is mostly done. Punch the hole from the upper side first. Many first-class horse-shoers punch only from that side, while most shoers punch from both sides.

There is no need of heating the shoe for punching the holes. Punch the holes next to the heel first, for if you punch the holes next to the toe when the shoe is hot, the punch will be hot, upset and bent. If it is a large shoe, punch only two holes on each side for the toe calk heat. These holes to be the holes next to the toe when the shoe is hot, and then punch the other two when you draw out the heel calks, and the shoe is hot at the heel. The heel calks should be as short as you can make them; and so should the toe calks. I know but a few horse-shoers that are able to weld on a toe calk good. The reason for their inability is lack of experience in general blacksmithing. Most shoers know not how to make a fire to weld in. They are too stingy about the coal; try to weld in dirt and cinders, with a low fire, the shoe almost touching the tuyer iron. I advise all horse-shoers to read my article about the fire.

I have made a hammer specially for horse-shoeing with a peen different from other hammers. With this hammer the beginner will have no trouble in drawing out the calks. See Figure 8, No. 8. The hammers as now used by most smiths are short and clumsy; they interfere too much with the air, and give a bump instead of a sharp cutting blow that will stick to the calk.

The shoe should be so shaped at the heel as to give plenty of room for the frog; the heels to be spread out as wide as possible. This is important, for if the shoe is wide between the heels the horse will stand more firm, and it will be to him a comfortable shoe. The shoe should not be wider between the calks at the expense of same, as is done by some shoers, for this is only a half calk, and the heel is no wider. The shoe should not be fitted to the foot when hot, as it will injure the hoof if it is burned to the foot.

The foot should be level, no matter what the fault is with the horse. The hoof should not be cut down more than the loose scales will allow. In a healthy condition this scale is a guide. When the foot is diseased it is different, and the shoer must use his own judgment.

The frog never grows too large. It should never be trimmed more than just to remove any loose scales.

The frog in its functions is very important to the well-being of the foot. In the unshod foot it projects beyond the level of the sole, always in contact with the ground; it obviates concussion; supports the tendons; prevents falls and contraction. The bars are also of importance, bracing the hoof, and should never be cut down as has been the practice for centuries by ignorant horse-shoers.

Forging or overreaching is a bad habit, and a horse with this fault is now very valuable. This habit can be overcome by shoeing; but it will not be done making the shoes short on the heel in front and short in the toe behind. Never try this foolish method.

To overcome forging the shoer should know what forging is. It is this: The horse breaks over with his hind feet quicker than he breaks over

Some writers make a difference between forging and overreaching, but the cause of the trouble is the same 葉oo much action behind in proportion to the front: and the remedy is the same羊etard the action behind, increase it in front. There are different ideas about the remedy for this fault.

One method is to shoe heavy forward and light be hind, but this is in my judgment a poor idea, although it might help in some cases.

|

The best way to shoe a forger or overreaching horse is to make a shoe for front of medium heft, not longer than just what is needed. The toe calk should be at the inner web of the shoe, or no toe calk at all, or, toe weight, to make the horse reach farther.

It will sometimes be found that the hind foot is shorter than the front foot. To find this out, measure from the coronet to the end of the toe. The shorter the foot the quicker it breaks over. If it is found that the hind foot is shorter than the front foot, then the shoe should be made so that it will make up for this. Let the shoe stick out on the toe enough to make the foot of equal length with the front foot. It is well in any case of forging to make the hind shoe longer on the toe. If the hind shoe is back on the foot, as is often done, it will only make the horse forge all the more, for it will increase action behind, the horse breaks over quicker, and strikes the front foot before it is out of the way. Set the shoe forward as far as possible, and make long heels. The longer the shoe is behind the longer it takes to raise the foot and break over.

Clack forging is meant by the habit of clacking the hind and fore-shoes together. This kind of forging is not serious or harmful; it will only tend to wear off the toe of the hind foot and annoy the driver, possibly a little fatiguing to the horse.

The position of the feet at the time of the clack is different from that it is supposed to be. The toe of the hind feet is generally worn off, while no mark is made on the front feet. From this you will understand that the hind feet never touch the heel of the front feet, but the shoe. Just at the moment the fore foot is raised up enough on the heel to give room for the hind foot to wedge in under it the hind foot comes flying under the fore foot, and the toe of the hind foot strikes the web of the toe on

Interfering is a bad fault in a horse. It is the effect of a variety of causes. In interfering the horse brushes the foot going forward against the other foot. Some horses strike the knee, others above it, the shin or coronet, but in most cases the fetlock.

Colts seldom interfere before they are shod, but then they sometimes interfere because the shoes are too heavy. This trouble disappears as soon as the colt is accustomed to carrying the shoes. Weakness is the most common cause. Malformation of the fetlock is another cause. The turning in or out of the toes, giving a swinging motion to the feet, is also conducive to interfering.

The first thing to do is to apply a boot to the place that is brushed. Next, proceed to remove the cause by shoeing, or by feeding and rest in cases of weakness. Nothing is better than flesh to spread the legs

|

Properly made and applied, side weight will stop interfering almost every time. If the side weight is heavy enough it will throw the foot out, and the trouble is overcome.

There are only a few horse-shoers that have any practical experience in making side-weight shoes, which we understand from the articles in our trade journals.

Some horse-shoers in shoeing to stop interfering will make common shoes shorter than they ought to be and set them far in under the foot, so that the hoof on the inner side will stick out over the shoe a quarter of an inch. These they don't rasp off, and everybody knows that the hoof adheres to and rubs harder against the leg than the hard smooth shoe. But, foolish as it is, such shoers stick to their foolish ideas. I call all such fads faith cures.

The rule is to have the side weight on the outer side, while the exception is to have the side weight on the inner side of the foot. For old and poor horses ground feed and rest is better than any kind of shoes. It will give more strength and more flesh to spread the legs.

Chapter 10

Chapter 8

Return to Main Page

© 2000, 2001 by Lynn Waterman